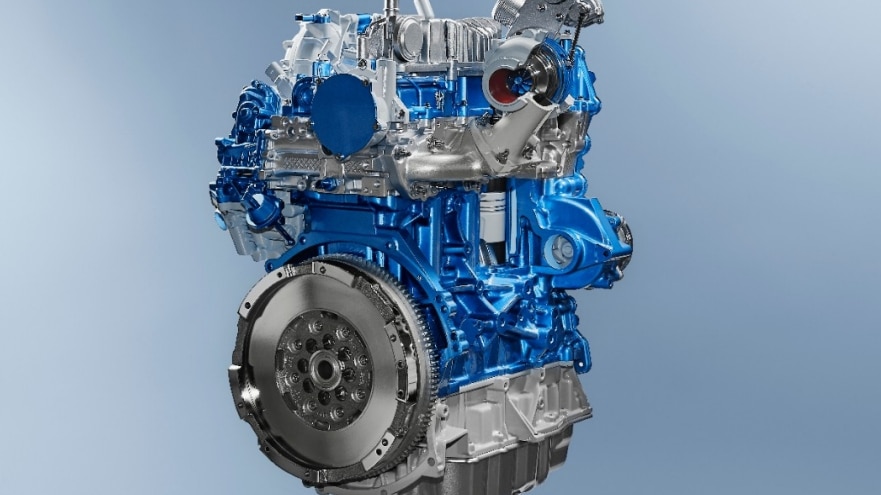

- Ford reveals all-new 2.0-litre Ford EcoBlue engine; first in a new range of advanced Ford diesel engines delivers unrivalled package of fuel efficiency, performance and refinement

- Clean-sheet design reduces friction with innovations including an off-set crank, belt-in-oil and Ford’s first use of modular camshafts for a 13 per cent fuel efficiency improvement

- Ford’s first mirror-image inlet manifold and a low-inertia turbocharger with rocket engine materials help deliver more than 20 per cent more low-end torque; enhanced drivability helps commercial vehicle drivers effortlessly tackle challenging everyday driving scenarios

- Standard selective catalytic reduction emissions after-treatment contributes to improved NOX reduction. Optimised engine structure reduces radiated noise by 4 decibels at idle

Download Fact Sheet (pdf)

BIRMINGHAM, U.K., April 26, 2016 – Ford today revealed the first new Ford EcoBlue advanced diesel engine that will offer optimised fuel efficiency and reduced CO2 and NOX emissions* for customers, using sophisticated technologies and innovative design.

Building on the industry-leading performance and technology of Ford’s award-winning EcoBoost petrol engines, Ford’s range of EcoBlue diesel engines will power the company’s future passenger cars and commercial vehicles with power outputs ranging from 100 PS to 240 PS.

The four-cylinder 2.0-litre Ford EcoBlue debuts in the new Transit and Transit Custom commercial vehicles, delivering an unrivalled package of fuel efficiency, performance and refinement.

Drivability is enhanced with 20 per cent more torque at 1,250 rpm compared with the outgoing equivalent power 2.2-litre TDCi diesel engine, helping commercial vehicle drivers effortlessly tackle challenging everyday driving scenarios such as creeping in traffic, or overtaking slower-moving vehicles. The new engine also delivers passenger car refinement to the commercial segment, reducing radiated noise by 4 decibels at idle.

“Ford’s EcoBoost created a new standard for petrol engines – smaller, more efficient with surprising performance. That same obsession to innovate for the customer is behind our new Ford EcoBlue diesel engine range,” said Jim Farley, chairman and CEO of Ford of Europe. “This new engine lifts fuel efficiency and reduces CO2 by over 10 per cent in Transit, part of Europe’s best-selling commercial vehicle line-up, lowering costs for our customers.”

An all-new engine architecture delivers reduced friction and a clean-burning combustion system. Sophisticated after-treatment processes for exhaust gasses enable ultra-low emissions in line with stringent Euro Stage VI standards that will be introduced in September 2016, requiring a 55 per cent reduction in NOx emissions compared to Euro Stage V standards.

Advanced technologies include an integrated intake system with Ford’s first application of mirror-image porting for optimised engine breathing; a low-inertia turbocharger featuring rocket engine materials designed for high temperature applications; and an all-new high-pressure fuel injection system that is more responsive, quieter and offers more precise fuel delivery.

Developed by Ford engineering teams in the U.K. and Germany, the versatile all-new 2.0-litre Ford EcoBlue engine initially will be offered with 105 PS, 130 PS and 170 PS in commercial vehicle applications. Capable of delivering more than 200 PS, the engine will later feature in Ford passenger cars alongside further new EcoBlue engines – including a 1.5‑litre variant.

Low friction, sophisticated combustion

The all-new 2.0-litre Ford EcoBlue engine’s clean-sheet design features multiple innovations that reduce friction, contributing to a 13 per cent improvement in fuel efficiency, including:

- A 10 mm offset crank design that minimises piston side-load, reducing rubbing forces against the cylinder walls of the downsized four-cylinder iron block

- Minimised crankshaft bearing diameters

- A belt-in-oil design for the camshaft and oil pump drive belts

- An optimised valve-train and an all-new single-piece camshaft module

Ford is for the first time using a new mirror-image porting design for the integrated inlet manifold that precisely controls the flow of air into the cylinders – with the clockwise airflow for cylinder numbers one and two, reversed for cylinder numbers three and four.

This symmetrical arrangement ensures uniform mixing of fuel and air in the combustion chambers of all four cylinders, helping engineers more closely control the way the engine burns fuel. When fine-tuning the combustion process, computer experiments used measurements from more than 1,400 factors that affect performance of the valve lift and timing alone.

“Our first ever mirror-image inlet design in combination with an optimised combustion chamber layout helps us turn fuel into energy more effectively than any diesel engine we’ve ever produced,” Dr. Werner Willems, Ford technical specialist, Combustion Systems.

New fuel injectors are capable of delivering up to six injections per combustion event, with each injection taking as little as 250 microseconds (0.00025 seconds) and delivering 0.8 mg of diesel – equivalent to a grain of sugar. This tiny volume of fuel is injected through eight conical holes each 120 microns in diameter – about the width of a human hair.

Piezoelectric technology that uses electrically-responsive crystals to closely control fuel delivery – typically found in premium passenger-car engines – is incorporated into the body of the injector unit. The new injectors deliver reduced noise levels; minimal energy wastage from the fuel pump; more responsive and less intrusive Auto-Start-Stop performance; and real-time calibration correction for maximum fuel efficiency.

Advanced turbocharging

The all-new compact turbocharger has been specifically designed to deliver more air at lower engine rpm compared with the outgoing 2.2-litre TDCi engine, for a light and urgent feel across the rev-range and up to 340 Nm of torque at 1,250 rpm.

An aerodynamically advanced turbine wheel – made from Inconel, an alloy used in extreme temperature environments such as rocket engines – is reduced in diameter by almost 10 per cent. The aerospace aluminium grade compressor wheel is reduced in diameter by 15 per cent. The reductions decrease inertia and enable faster boost performance with wheel speeds up to 240,000 rpm, contributing to improved low-end torque.

“One important factor we noticed through customer feedback is a growing tendency for drivers to ‘creep’ their diesel powered vehicles by engaging the clutch while the engine is at idle – making low-down torque even more essential,” said Paul Turner, base engine technical leader, Ford of Europe.

Compressor wheels are milled from solid, rather than cast, improving tolerances to within two or three microns – around the size of a single bacterium – increasing durability and reducing noise and vibration. A new turbocharger actuator replaces a worm drive with a geared design that halves response times to 110 milliseconds – or the blink of an eye.

The new engine will comfortably meet future European emissions requirements supported by Ford’s first standardised selective catalytic reduction system. The system is close-coupled to the rear of the engine for maximum efficiency and excellent cold-driving performance. A short-loop exhaust gas recirculation channel is incorporated into the cylinder head, contributing to a more compact engine design and helping optimise cooling of gasses.

Enhanced refinement

The 2.0-litre Ford EcoBlue engine will be the first diesel commercial vehicle powertrain from Ford to achieve passenger car noise, vibration and harshness criteria, contributing to enhanced driving appeal.

The new engine radiates half as much sound energy at idle as the 2.2-litre TDCi diesel engine. A noise-optimised a cylinder-head, block, stiffening ladder-frame and oil pan are specifically developed to be desensitised to activity inside the engine, and non-flat mating surfaces are carefully designed to offer tight seals that trap noise within the engine.

“The basic structure of an engine can act as a soundboard for the movements happening inside it, just like a bell. So we try to develop a bell that does not ring very well,” said Dominic Evans, NVH specialist, Ford of Europe. “We’ve engineered every significant noise-influencing component of this engine to be quieter and smoother operating – resulting in the most refined diesel commercial vehicles Ford has ever built.”

A moulded acoustic cover that provides foam encapsulation of the cylinder head, and a front cover made from sound deadened steel, further prevent engine noise being transmitted to the cabin for a quieter driving environment. Additional measures taken to enhance NVH include:

- Micro-geometry analysis of gear teeth down to a micron level (0.001 mm) to achieve perfect meshing for smoother operation and less high-frequency whine

- An optimised oil pump featuring unevenly spaced vanes that break up the pump’s noise frequency to make it less perceptible to the listener

- Advanced fuel injectors featuring integrated piezo-stacks, noise softening software and optimised pilot injection

Commercial vehicle durability

The new 2.0-litre Ford EcoBlue engine meets Ford's demanding global commercial vehicle durability standards for extreme usage in markets as diverse as Europe, the U.S. and China.

The engine's performance has been trialled through the equivalent of 5.5 million km (3.4 million miles) of durability testing including 400,000 km (250,000 miles) at the hands of real-world customers, comprehensive analysis in laboratories and at Ford vehicle proving grounds, and CAE evaluations at every stage of development.

The oil system – including the oil specification, oil pan and filter dimensions, bore distortion tolerances and piston ring specifications – has been engineered to extend oil life, and maintenance-free components include the camshaft belt, camshaft module, and water pump.

“We developed the 2.0-litre Ford EcoBlue engine using feedback from customers around the world,” Turner said. “The versatile design even allows the same block to be used for front-wheel drive and rear-wheel drive applications, and the sophisticated design and technologies deliver future-proofed fuel efficiency and emissions.”

# # #

* The declared Fuel/Energy Consumptions, CO2 emissions and electric range are measured according to the technical requirements and specifications of the European Regulations (EC) 715/2007 and (EC) 692/2008 as last amended. Fuel consumption and CO2 emissions are specified for a vehicle variant and not for a single car. The applied standard test procedure enables comparison between different vehicle types and different manufacturers. In addition to the fuel efficiency of a car, driving behaviour as well as other non-technical factors play a role in determining a car's fuel/energy consumption, CO2 emissions and electric range. CO2 is the main greenhouse gas responsible for global warming.