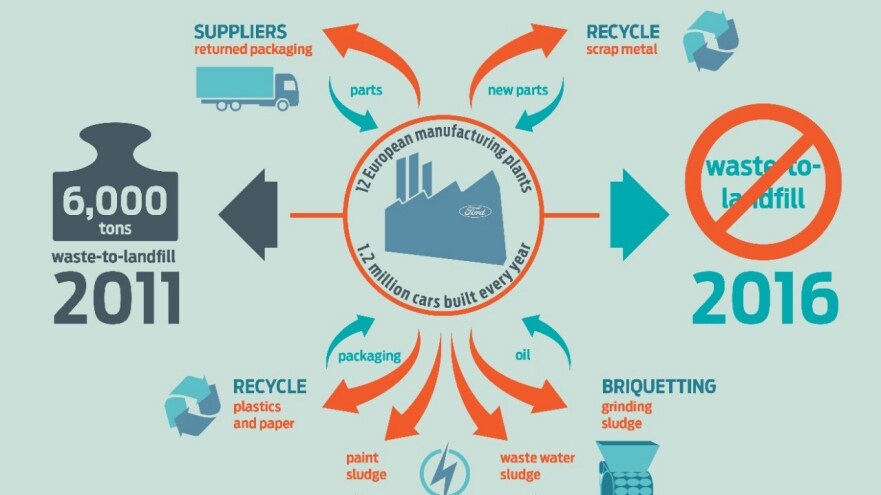

- Ford of Europe’s manufacturing plants reduce the amount of waste destined for landfill sites from an annual 6,000 tonnes to zero in just five years

- Latest plants to achieve zero waste-to-landfill status are Valencia, in Spain, and Craiova, in Romania; 12 manufacturing plants in Europe now recycle, reuse or repurpose all waste

- Ford’s recently published 2016 Sustainability Report highlights further global achievements in sustainable manufacturing, supply chain sustainability, quality and safety; documents consistent improvement in use of critical resources like water and energy

Please click here to download the Infographic (PDF)

COLOGNE, Germany, June 30, 2016 – Ford of Europe has achieved zero waste‑to‑landfill at all of its European manufacturing plants. This reduces by 6,000 tonnes each year the amount of waste sent to landfill compared with 2011 – equivalent to the annual waste discarded by a town of 12,500 people, for the 1.2 million vehicles that Ford produces in Europe each year.

Innovative measures employed to achieve zero waste-to-landfill include the briquetting of grinding sludge from the Dagenham engine plant, in the U.K., so that the oil can be re-used in the production process. At the Valencia plant, in Spain, Ford pioneered generating alternative fuel from waste that could not be recycled.

“We have introduced a range of measures that have not only significantly reduced our reliance on landfill for our manufacturing plants, but removed it entirely. This achievement is a fantastic base to push on from and further improve in areas such as water and electricity usage reductions as Ford of Europe drives towards the company’s global sustainability ambitions,” said Andreas Reiss, manager, Environmental Quality Office Europe, Ford of Europe.

The latest plants in Europe to achieve zero waste-to-landfill status are Valencia, and Craiova, in Romania, which join plants in Bordeaux, in France; Bridgend and Dagenham, in the U.K.; and Cologne and Saarlouis, in Germany.

Ford recently published its 2016 Sustainability Report, highlighting global achievements in areas including sustainable manufacturing, supply chain sustainability, quality and safety. The company is deeply committed to running a responsible business that treats its customers, employees, communities, and the planet with respect.

In 2015, Ford in Europe rolled out a new Energy Management Operating System within the Ford Production System, enabling teams to manage demand and remotely control plant energy and heating systems for greater energy efficiency. This is part of an energy strategy that has resulted in a 25 per cent reduction in energy use compared with 2011, equivalent to an annual saving of 800 gigawatt hours. Between 2013 and 2015 Ford also has reduced its global water usage per vehicle produced to 3.81 cubic metres from 4.04 cubic metres and decreased carbon dioxide emissions per vehicle produced from 0.78 metric tons to 0.72 metric tons.

Please click here to download the Infographic (PDF)