- Ford employees are tasked with secretly planting wrong and faulty parts onto the assembly line, including incomplete steering wheels and faulty engine components

- “Gremlin Tests” help deliver on Ford’s commitment to quality, alongside industry-first digital photo tech that records, checks and traces all vehicle parts at mega plant in Valencia, Spain

- Vision System takes more than one billion photographs every 14 days – comparable to the number of photographs uploaded to Instagram in Europe

Meet Xabier Garciandia, whose working day involves literally trying to put a spanner into the works of one of the world’s most advanced auto plants – by making sure wrong parts and faulty components are secretly placed on the assembly line.

But rather than working for unscrupulous rivals, Xabier is actually a key part of the process of making sure all new vehicles built at the plant meet Ford’s rigorous quality standards.

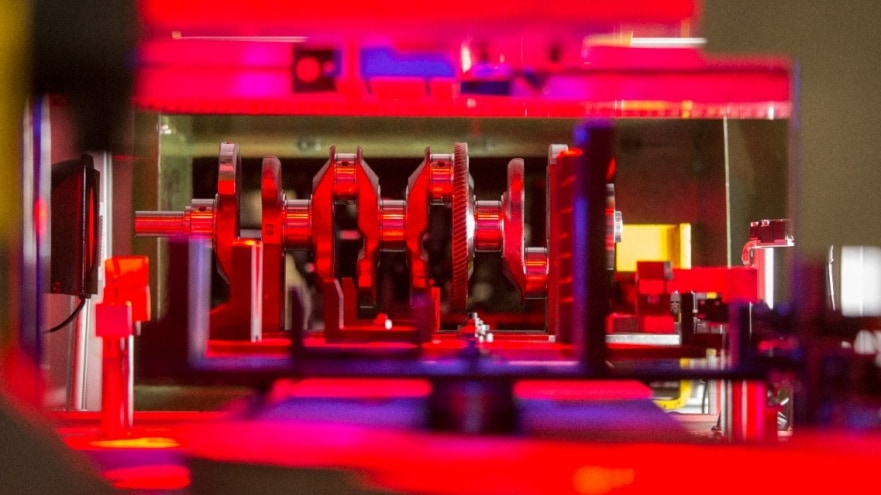

Ford’s industry-first Vision System technology photographs, checks and tracks every single part of each of the 400,000 cars and vans assembled, and 330,000 engines built at Valencia each year. “Gremlins Tests” are an innovative way of ensuring that new process is working correctly.

“The Vision System is crucial to ensuring every single part of each vehicle is just right,” said Garciandia, technical specialist, Valencia Engine Vision System, Ford of Europe. “The ‘Gremlin Test’ means we can ensure that system is working perfectly. It is a game with a very serious point. The team are really excited when they find one of our parts and all the time we are making them harder to spot.”

Ford produces more Ford models at the state-of-the-art Ford mega plant in Valencia than anywhere else in Europe, including Kuga, Kuga Vignale, Mondeo, Mondeo Vignale, Galaxy, S-MAX and Transit Connect and Tourneo Connect. Also produced at Valencia are Ford’s 2.0-litre and 2.3-litre Ecoboost engines. The Vision System captures more than a billion photos every fourteen days, comparable to the number of photos uploaded to Instagram in Europe. * This also helps to generate a composite image – consisting 3,150 digital photographs – that highlights any discrepancies to engineers on the spot.

In Valencia so far, faulty engine parts, wrong steering wheels, and even incorrect dashboards have been sent down the line, with the “Gremlins Test” now extended to all 34 stages of assembly, and Ford considering for roll-out worldwide.

“The way in which we all use digital cameras has totally changed the way we record our daily way of life, and is now transforming the way we build engines and cars,” said Garciandia. “But we also have to test the tests, and we are doing this in a way that is very simple, but which we believe is unique in the auto industry.”

Ford has introduced a range of rigorous and in some instances unusual quality processes at the plant where a new vehicle rolls off a single production line every 40 seconds.

These include:

- Ultra-sensitive microphones used to register engine connectors have been installed

- “Engine listeners” ensure each new Ford Focus RS hot hatch is running flawlessly

- Ostrich feathers that are used to dust models before painting to enhance paint finish

- An industry-first digital camera system that identifies vehicle bodyshell paint defects

- Vehicle audio testing that reflects customers use of audio streamed via Bluetooth

- A virtual rolling road test to evaluate advanced driver technologies

# # #

Suggested Photo Caption:

Ford’s new “Gremlin Tests” secretly plant wrong and faulty parts onto the assembly line at the company’s mega plant in Valencia, Spain, to check industry-first digital photo system is working correctly

* https://searchenginewatch.com/2016/04/20/23-stats-and-facts-about-instagram/