Sep 12, 2013

Celebrating the Moving Assembly Line in Pictures

On Oct. 7, 2013 Ford will celebrate the 100th anniversary of the innovation that made the largest impact on manufacturing, industry and society as a whole: the moving assembly line.

Not only did the moving assembly line drastically increase the pace at which cars were produced, it also drove down the price of each car making them more accessible to the masses.

Bringing the product to the worker instead of moving various teams of workers to the product became the idea that overhauled the manufacturing industry as a whole. A new standard had taken over making it possible to generate more products and greater income through mass production.

The pictures below tell a story of just how innovative the moving assembly line was at its genesis and how continued progress has refined the process over the last ten decades.

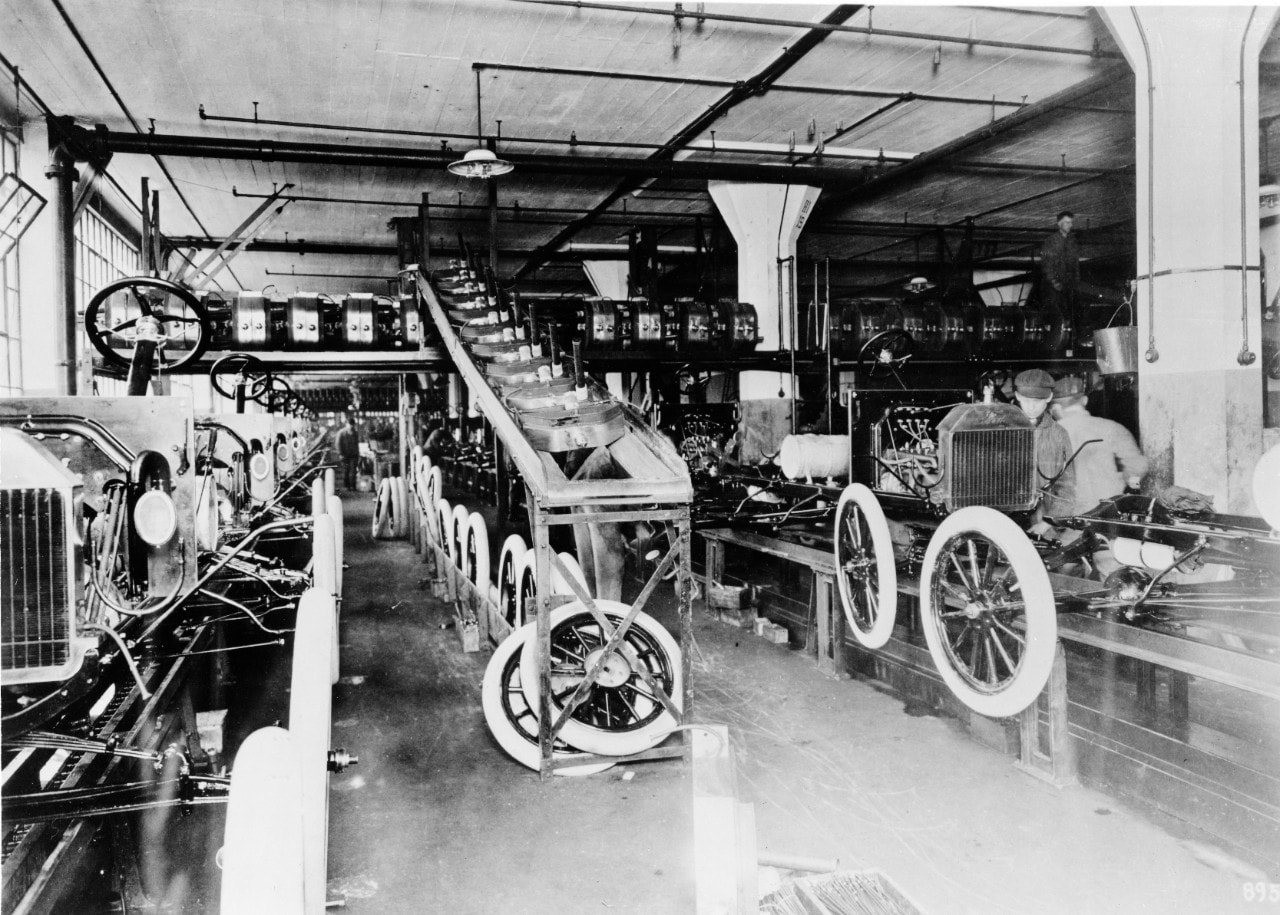

Early Model T assembly at Highland Park Plant

Thanks to the moving assembly line, Ford was able to produce the 10 millionth Model T by 1924

As the company expanded, plants like this one in Dallas, Texas sprouted up around the world

By 1941, the vehicles coming down the line had changed significantly adding elements of complexity to the line as they developed

A crew inspects an engine circa 1946

A line of Mercurys reaching the final assembly stage in 1946

Dearborn Assembly Plant in 1954

Before ergonomic design made its way into the plants, some workers worked alongside the vehicles while others made progress in the pits below

Placing the engine into a Ford Boss 429 Mustang in 1969

Placing an F-Series bed onto the frame at the Louisville Assembly Plant, 1973

A team performing quality control duties at Dearborn Assembly in 1975

F-Series trucks undergoing inspection at Twin Cities Assembly

In this 2004 shot of Mustangs being produced at Flat Rock Assembly, we see the mechanization of the assembly line

More robotics in place in 2008 at the Fiesta Assembly Line at Cologne-Niehl

While machines and robots have been introduced into plants to reduce physical stress on workers and increase productivity, people still play the most vital role in bringing a car together

Improved processes and ergonomics, as displayed here in 2012 at the LAP plant, have brought many workers out of the pits and into a safer, healthier work environment