A version of this piece was published in the 2024 Docomomo Corporate Campus Newsletter.

The Ford Motor Company corporate campus is located about 10 miles west of Detroit in the city of Dearborn. Ford first began purchasing property here along the Rouge River in 1915, but it was not until 1917, with the impetus of World War I, that they completed the first structure to produce eagle boats for the war effort.

Countless additions later, the Rouge complex, now referred to as the Ford Rouge Center, is still operational and is itself an exemplar of adaptive reuse. The expansion of production at the Rouge anchored Ford in Dearborn, where the company would continue to expand its campus, especially after World War II.

Albert Kahn designed most of these early Rouge constructions. Kahn was beyond prolific in his partnership with Ford, designing hundreds of other buildings in Dearborn, around the country, and internationally. While his work can be found around the world, Kahn is recognized as the preeminent Detroit industrial architect of his time, inadvertently also serving as the inspiration for early Modern architects. His work in Detroit is also quite varied as he designed several factories (not just for Ford), public buildings, schools, and private homes, including the home of Edsel and Eleanor Ford. He worked very closely with Henry Ford on many of the commissions he completed on behalf of the Company, with the Ford Engineering Laboratory as one of the most notable.

The Ford Engineering Laboratory and The Human Bridge

This year marks the centennial of the Ford Engineering Laboratory’s (FEL) construction. Over the last century the historic structure underwent several additions and redesigns to keep up with shifting uses for the space. When completed, the Dearborn Engineering Laboratory, as it was first referred to, housed all that was necessary to design and test the entire vehicle. Upon opening, FEL was considered one of the largest open office spaces of its time. The main workspace is essentially one large room. The openness lent itself to adaptive reuse over the years as new buildings were added to the Ford Dearborn campus and the Company relocated business functions.

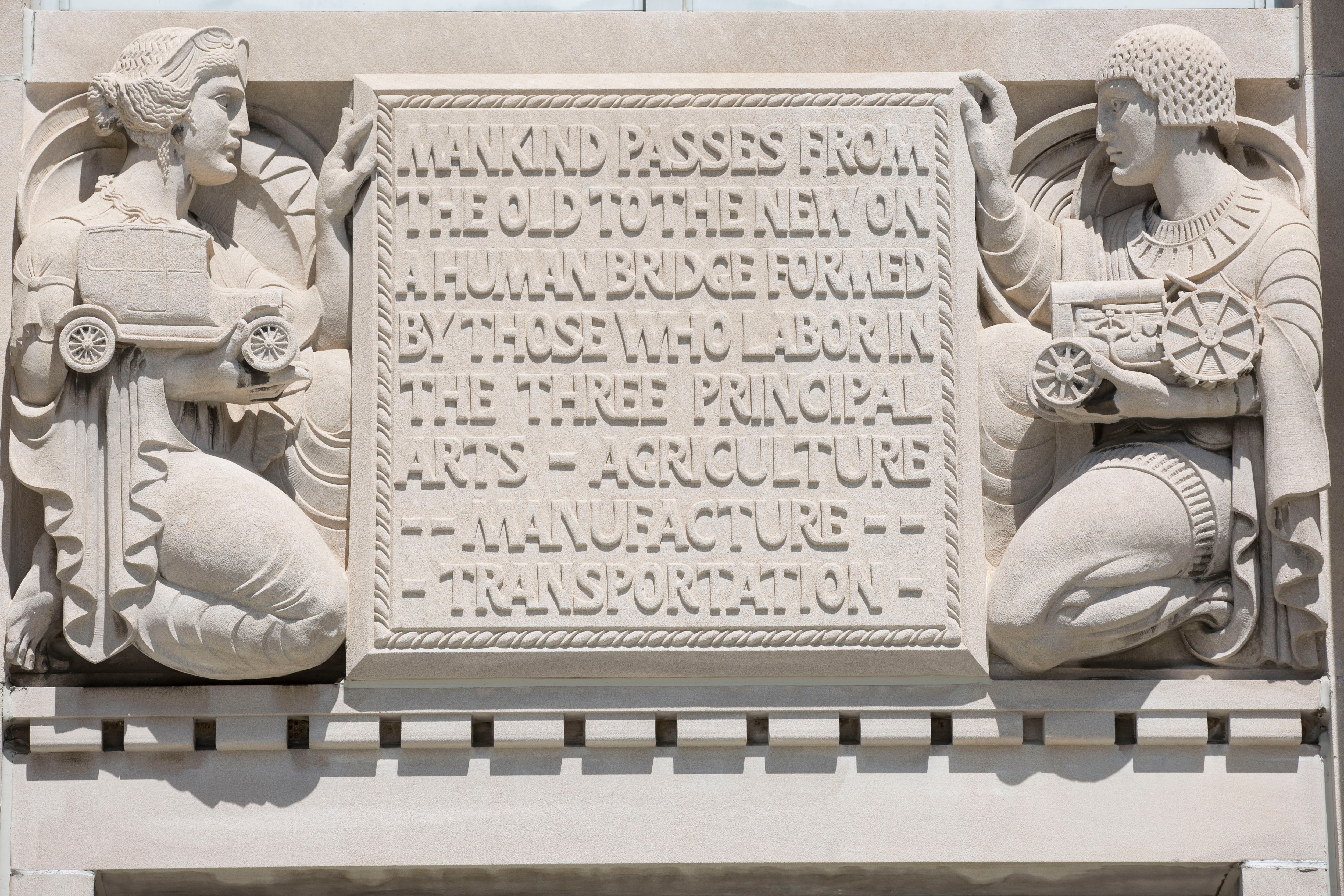

On the façade of the building, it reads: “Mankind passes from the old to the new on a human bridge formed by those who labor in the three principle arts – agriculture – manufacture - transportation-“

“The Human Bridge” is also the title of a film produced by Ford in 1949, which begins with a close up of FEL’s façade and this same Beaux-Art relief. The moving image lays out the incredibly involved process of creating a vehicle from the design stage all the way to rolling off the line and onto the streets. We see images of stylists in FEL’s open space adjusting elements of the initial design, modelers piling on and deftly shaving away clay, hunched designers sharing space in a sea of drafting tables, and experimental engineers lowering an engine. The model that rolls off at the end is the 1949 Super Deluxe, one of Ford’s first passenger cars produced after World War II. The Super Deluxe eventually finds itself sharing the road with its much older counterpart: the Model T. In an unintentionally comic move, it swiftly passes the old timer, with both drivers giving one another a friendly wave.

At the time this was meant to demonstrate the modernization of the processes, some of which Ford had revolutionized, that went into vehicle production. The passing of the torch from team to team appears almost as an endless cycle, made up of countless workers and their streamlined cooperation. While a bit on the nose, this same concept of the human bridge is ever-apparent in the life of the Ford Engineering Laboratory and its extended reuse.